200W backpack pulse laser cleaning machine rust removal - Bulk Cloned

1. Non contact cleaning, without damaging the component substrate;

2. Accurate cleaning, which can achieve selective cleaning of precise positions and sizes;

3. Simple operation, no need for any chemical cleaning solution, no consumables, safe and environmentally friendly;

4. Ergonomic design greatly reduces labor intensity during operation;

5. High cleaning efficiency and time saving;

6. The laser cleaning system is stable and requires almost no maintenance;

7. Optional mobile battery module.

video

Product Parameters

| Operating environment | |

| Name | YFPN-200-GMC-B |

| Powered | Optional battery, 100W continuous work for 1h |

| Standard single-phase 220V:10%50/60Hz AO | |

| Machine power consumption | <500W |

| Working temperature | 5°C~40°C |

| Working environment humidity | <80% |

| Optical parameters | |

| Average laser power | ≥200W |

| power instability | pulse |

| Way of laser working | <2% |

| Pulse Width | 10-500ns adjusted |

| Max. single pulse energy | 1.2mJ |

| beam quality (M2) | <2.0 |

| Power adjustment range | 10-100%(Gradient adjustable) |

| repeat frequency | 1-3000kHz (Gradient adjustable) |

| Cooling method | Air cooling |

| Cleaning head parameters | |

| Scanning range (L* W | 0-100mm,Continuously adjustable: |

| Dual axis supports 8 scan modes; | |

| scanning frequency | 10Hz-300Hz Continuously adjustable |

| Field lens focal length | 160mm (210mm/254mm/330mm/420mm for optional) |

| Depth of focus | Around 5mm |

| Mechanical parameters | |

| Overall size | Around 336mmx129mmx540mm |

| Total Weight | Around 16Kg (with battery) |

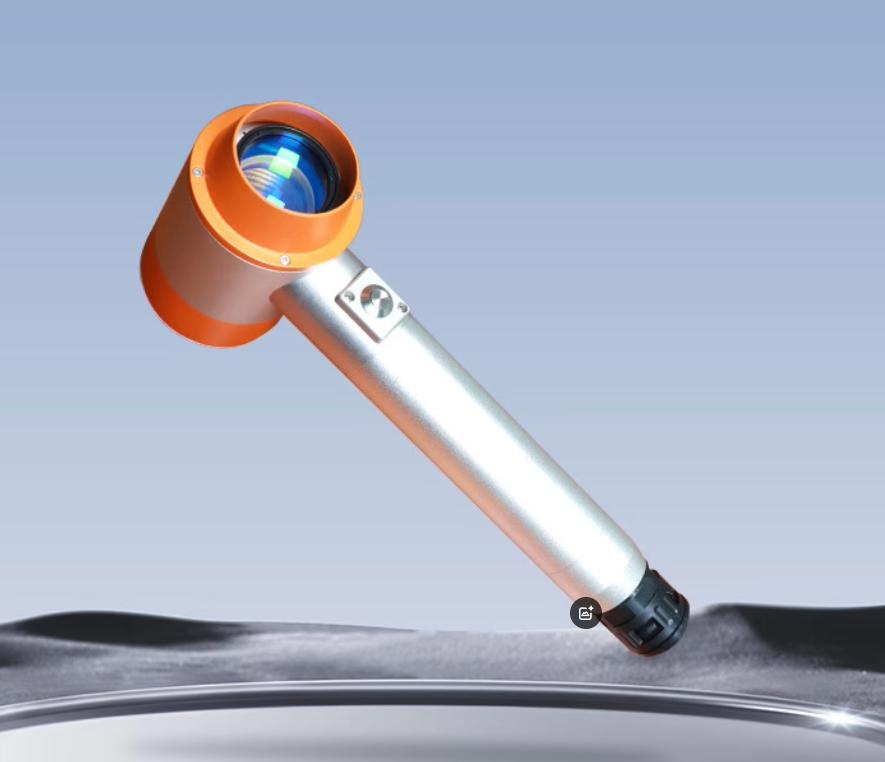

| Operation method | Hand held |

Product Advantages

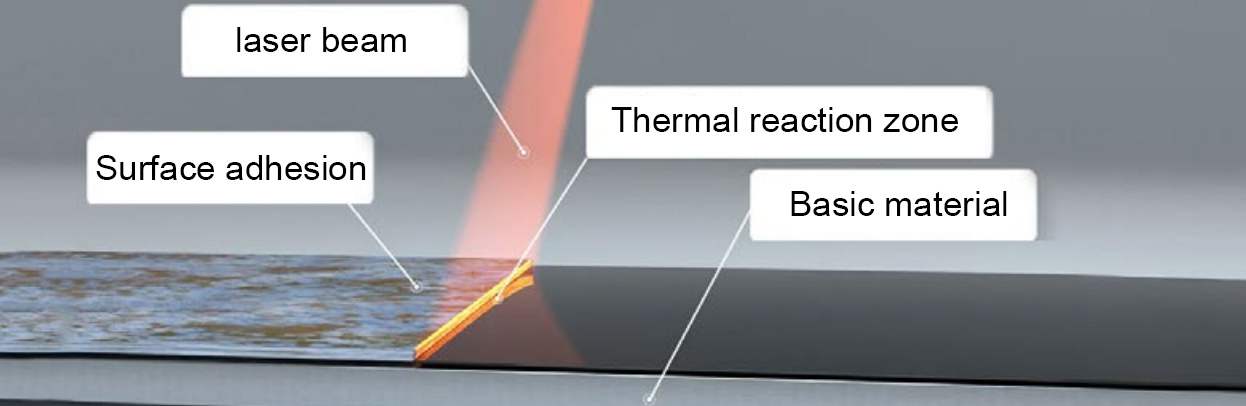

Compared with the traditional mechanical cleaning method, chemical cleaning method and ultrasonic cleaning method, Laser Cleaning does not damage the base material during processing, no pollution, high efficiency and environmental protection

The pulse laser cleaning machine will not damage the substrate and can thoroughly clean dirt

Conventional cleaning materials include aluminum products, copper products, stainless steel products, etc. It can remove oxides, grease, and dirt from the surface, restoring luster to the metal surface. It can also distinguish non-metallic materials, including plastic products, glass products, stone products, etc. It can remove surface dirt and scratches, making the surface of items smoother.

Easy to operate, time-saving and labor-saving. The design concept of the product is portable and can be carried with a backpack. One person can lift the entire machine, weighing only 16 kilograms (including batteries). Handheld cleaning head, ergonomically designed to greatly reduce user labor intensity.

Visual operation interface, supporting multiple language switching. The product is safe and environmentally friendly, with no chemical cleaning solution during use and no additional consumables loss.

Application Industry

Portable laser cleaning machines are widely used in industries such as shipbuilding, automotive parts, rubber molds, high-end mechanical tools, tire molds, tracks, environmental protection industry, and weapon equipment industry。

Related Products

Submitted successfully

We will contact you as soon as possible