500-100000W Fiber laser

Radium source of development of electric control system of fiber laser solutions, can let the customer focus on laser optical parts, electrical control part we have a complete solution, can drive the imlet road 210, 53 mw output power, can also according to customer's request separate custom laser electronic control system, the machine can realize optical power of 100000 w! 500-100000W optical fiber laser electronic control and drive system solutions

Radium supply of electronic manage device solutions for the improvement of fiber laser, can let the client awareness on laser optical components, electric manipulate element we've a whole answer, can pressure the imlet street 210, fifty three mw output energy, can also in step with patron's request separate custom laser electronic control machine, the system can realize optical electricity of one hundred thousand w!

Users can quickly develop their own Fiber laser electronic control system with over-current, optical power abnormal multiple high-speed protection, high-speed thermal management and protection, 100US fast system protection after failure, to ensure the safety of the laser!

Main characteristics of electronic control drive system for Fiber device

1. Realize the whole laser control mode switching and saving function.

2. Detect the temperature and humidity in one cabinet.

3. One RS485 communication port for communication control with the external host.

4. One RS485 communication port is used for communication control with the inner core board in the constant current driver.

5. One way water pressure detection function; Three way indicator light output function, used for power on normal indicator, light indicator, alarm indicator; External analog input function, used to control and adjust the constant current drive output current.

6. External enable function, used to control the main switch of constant current drive output. Modulation signal input function, used to control constant current drive work fast modulation current output. One way QBH detection function

The whole system control mode has two kinds: the first software upper computer control mode (including debugging)

The second external analog control method; The drive and control part includes: a kernel control board and a multichannel constant current drive board. The functions are: a PD detection function; One way red light control function; One way internal temperature, temperature and humidity detection function; An inner core board controls the multichannel constant-current drive board function.

Electronic control and drive system solutions

Detailed introduction of related products

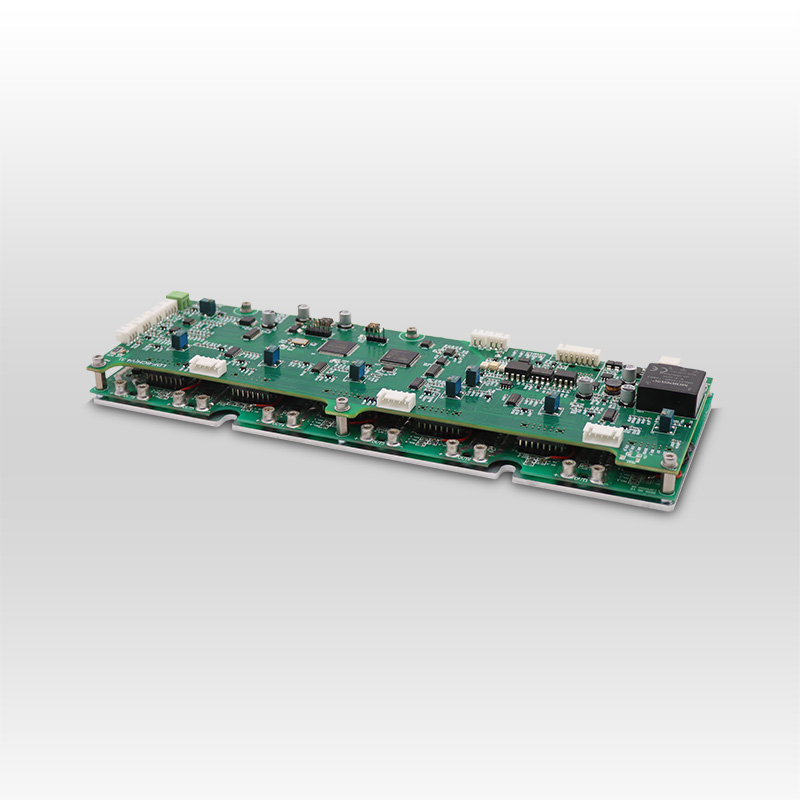

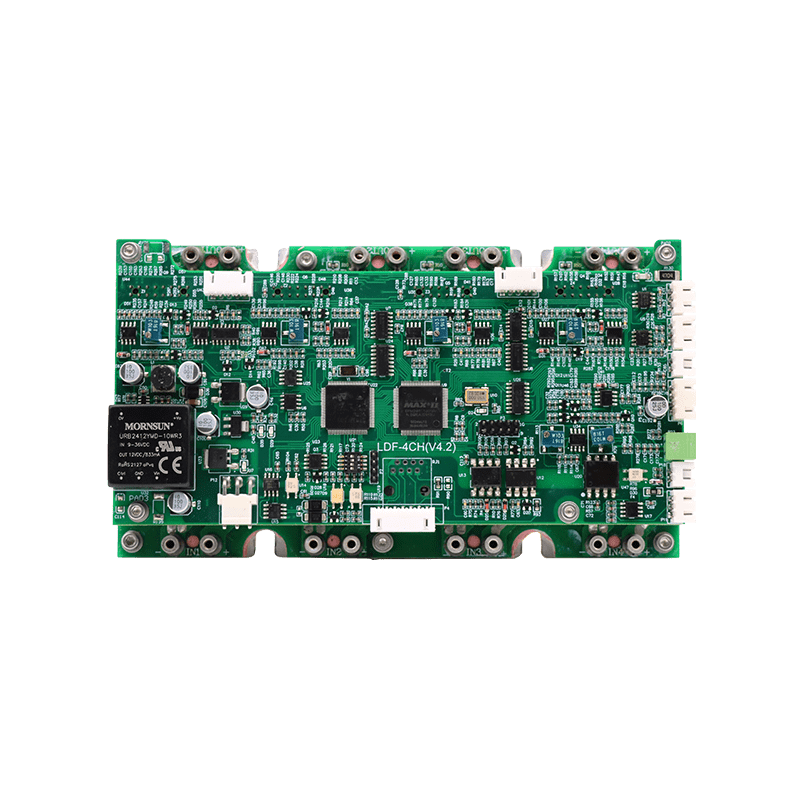

Integrated driver module for four continuous fiber lasersProduct Features

4*20A independent constant current drive output, each output current software can be adjusted/enabled to control;

The main control board can be expanded to 16*4=64 channels of constant-current control output,

and the synchronization difference of each channel shall not exceed 2uS when switching.

Constant-current output current ± ≦ 10US; No overshoot/recoil;

Constant-current output ripple ≦ ±0.2%; The comprehensive adjustment rate of constant current ≦ ±0.5%;

Output voltage/current: customized according to actual needs; Can be set and stored;

Overtemperature, overcurrent hardware and software interlocking protection,

PD hardware interlocking protection, protection response time ≦ 50US, to ensure the safety of the laser!

Input voltage detection, undervoltage, overvoltage alarm, easy debugging;

High speed accurate power adjustment tube thermal management function,

independent hardware overcurrent protection

Multi-channel laser power PD, temperature, humidity, flow switch and other real-time detection and control;

With indicator drive and control;

It can be equipped with a special constant voltage source to reduce power consumption

and adjust the difficulty of input voltage.

Application: MOPA Fiber laser pump source drive and control.

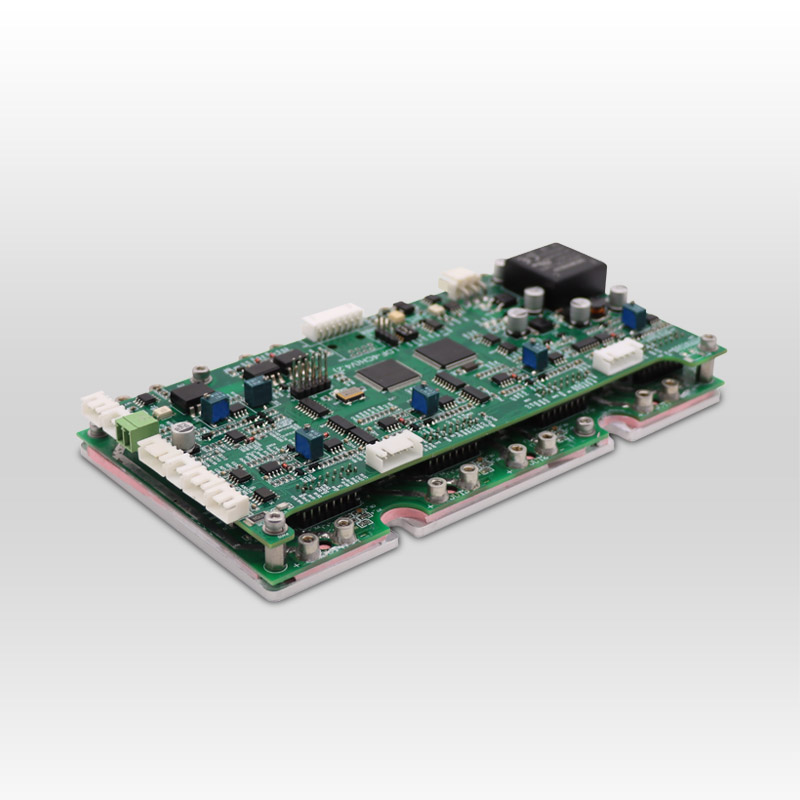

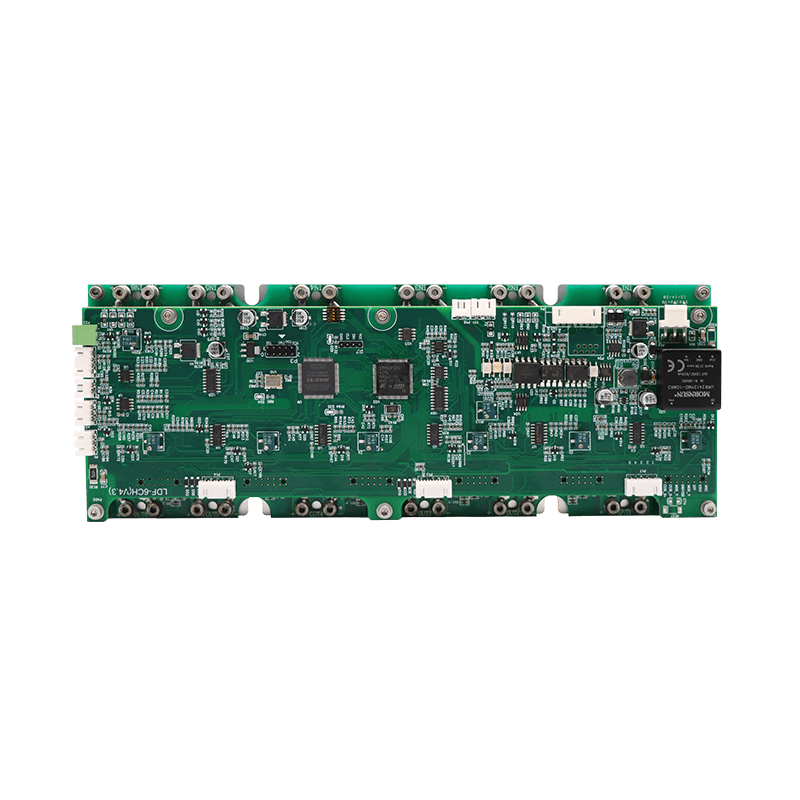

Integrated driver module for a 6-channel continuous fiber laserProduct Features

6*20A independent constant current drive output, each output current software can be adjustable

It can be expanded to 16*6=96 channels of constant-current control output through the dedicated main control board,

and the synchronization difference of each channel shall not exceed 2uS when switching.

Constant-current output current ± ≦ 10US; No overshoot, no recoil;

Constant-current output ripple ≦ ±0.2%; The comprehensive adjustment rate of constant current ≦ ±0.5%;

Output voltage/current: customized according to actual needs; Can be set and stored;

Over temperature, over current hardware, PD hardware interlocking protection,

protection response time ≦ 50US, to ensure the safety of the laser!

Input voltage detection, undervoltage, overvoltage alarm, to achieve efficiency, convenient debugging;

Power adjusting tube thermal management function, to ensure the power tube work safety;

Independent hardware overcurrent protection to avoid overcurrent damage of the rear band laser;

Multi-channel laser power PD, temperature, humidity, flow switch and other real-time detection and control;

With indicator drive and control;

Can be matched with a dedicated constant voltage source, reduce power consumption, increase reliability,

reduce the difficulty of adjusting the input voltage.

Application: MOPA Fiber laser pump source drive and control

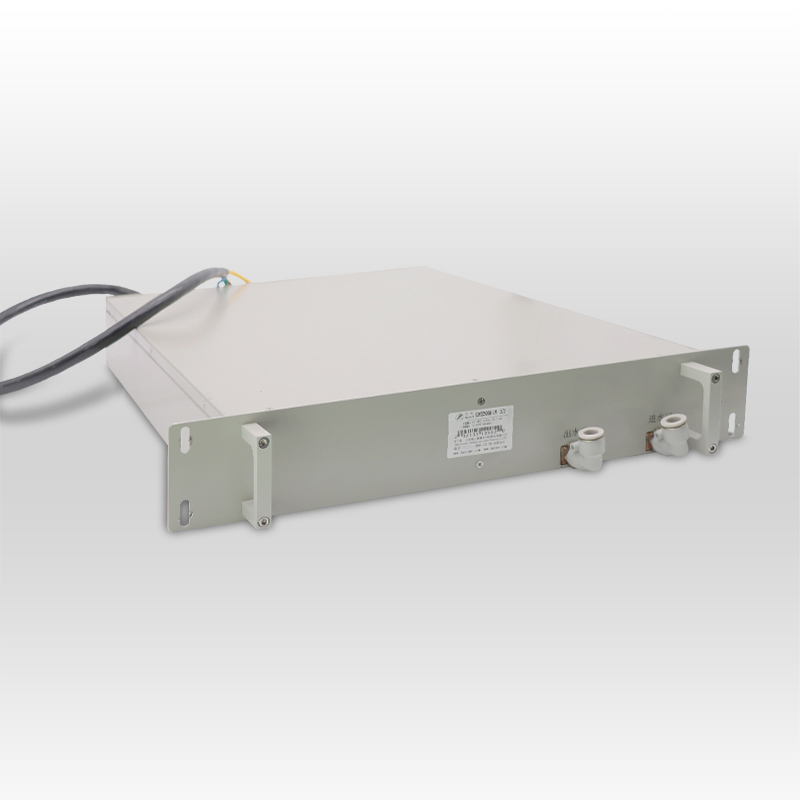

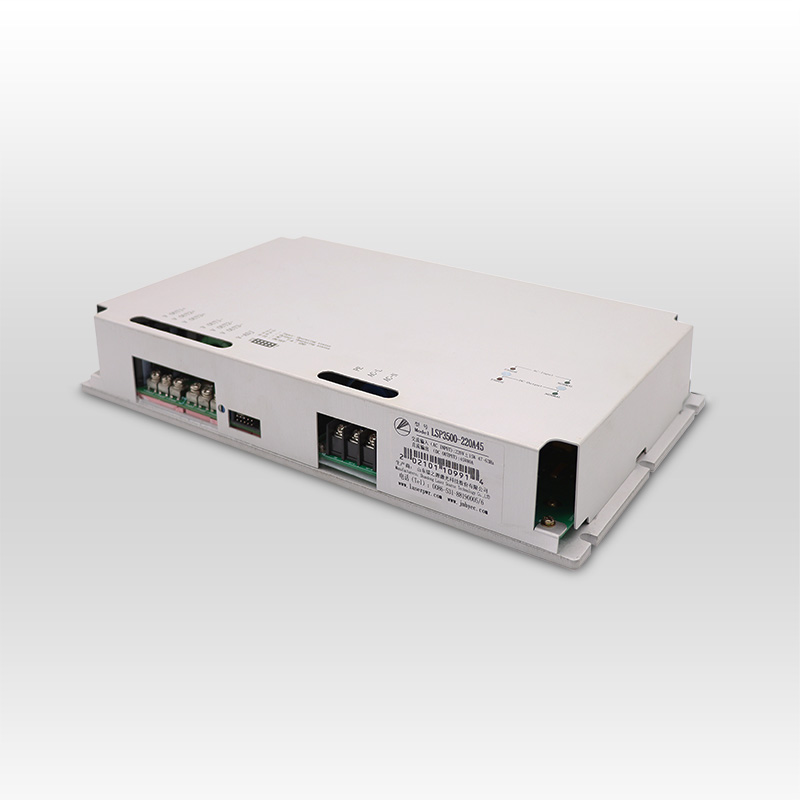

ACDC water-cooled ultra-thin constant voltage fiber laserProduct Features

Built-in active PFC, wide input voltage range;

Multi-resonant soft switching technology, high efficiency, high power density;

The machine has high precision, reliable, safe and stable performance;

Output voltage ripple: ±0.5%VO; Output voltage comprehensive adjustment rate: ±0.5%;

Strong output load capacity, 0-5khz pulse current output voltage variation is not more than ±0.5%VO;

Output with short circuit protection, over current protection, over temperature protection; Fault status is displayed and fault information is reported.

The output voltage can be automatically adjusted according to the pump source voltage needs (with our special driver module), improve the efficiency of the whole constant current drive, and simplify user debugging;

Accept external switch control, water cooling heat dissipation.

Application: Pre-constant voltage AC/DC module for high-power fiber laser

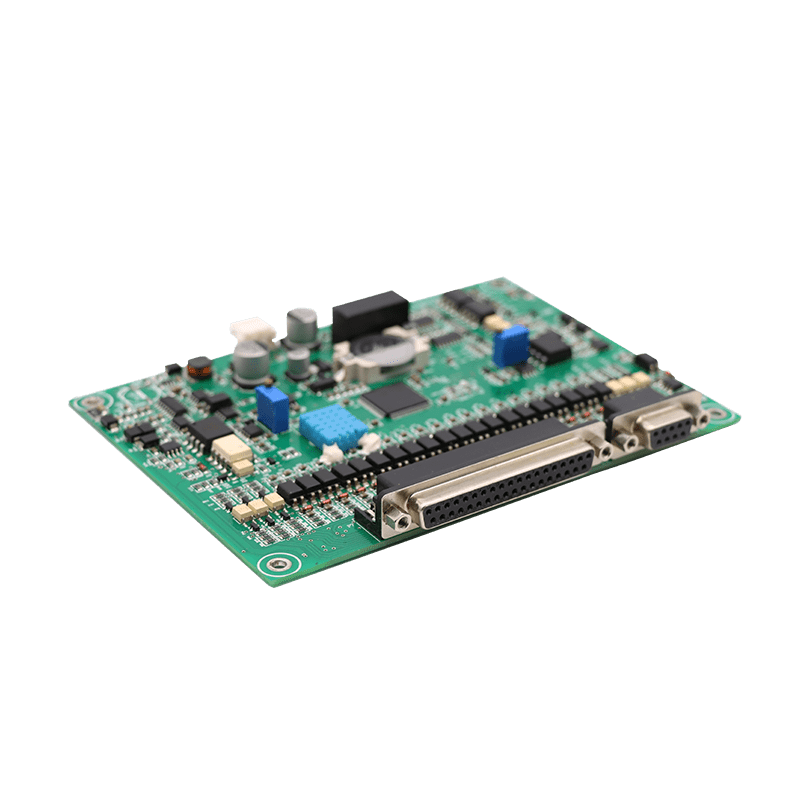

Optical fiber semiconductor laser power supply main control board product features

The integrated drive module of fiber laser is extended to the control center of 120 channels drive.

With external control interface and communication interface, can be local control,

remote software control, remote simulation control;

With a large capacity memory chip and RTC real-time clock, can store parameter Settings, waveform editing,

running records, fault records, etc., and can be called;

Equipped with upper computer software, with debugging mode, running mode;

In debugging mode, the driving current value, temperature and humidity limit, overcurrent limit,

optical power (PD check value) limit, voltage limit and so on can be set, and PD detection can be automatically calibrated.

In operation mode, it can detect and display operation parameters such as voltage, current, temperature and humidity,

optical power and fault information in real time, and respond to external signals in real time.

Manage light out warning, power on indicator, light out indicator output, main power on, key switch, emergency stop, etc.

Related Products

Submitted successfully

We will contact you as soon as possible