fiber laser rust removal

4-6 channels *20A independent constant-current drive output, each output current software can be adjustable and enabled to control respectively.

The output of 30*6=180 constant-current control channels can be extended by a dedicated main control board, and the synchronization error of each channel does not exceed 1uS when switching.

Output voltage 20-180V adaptive (maximum constant-current current decreases with increasing output voltage).

Module power up to 9KW.

The rising and falling edge of the constant-current output current is less than 10US; No overshoot, no recoil.

The output current ripple of constant current is less than ±0.2%; The comprehensive adjustment rate of constant current is less than ±0.5%.

Operating parameters, linkage protection value, alarm value, calibration PD, etc. It can record the running time, store 24 groups of running parameters for direct invocation, store fault records for analysis and upload.

Several control methods: local control, remote RS485 communication control, remote simulation control.

Overtemperature, overcurrent hardware, software interlocking protection, PD hardware interlocking protection to ensure the safety of the laser.

Input voltage detection, undervoltage and overvoltage alarm, to achieve optimal efficiency and facilitate debugging at the same time.

The thermal management function of high-speed accurate power adjustment tube ensures the safety of power tube.

Independent hardware overcurrent protection absolutely avoids overcurrent damage of the rear-band laser.

Real-time detection and control of multi-channel laser power PD, temperature, humidity, flow switch, etc.

Bring the indicator CD drive and control.

A feedforward dedicated constant-voltage source can be developed to reduce power consumption, increase reliability and reduce the difficulty of adjusting the input voltage

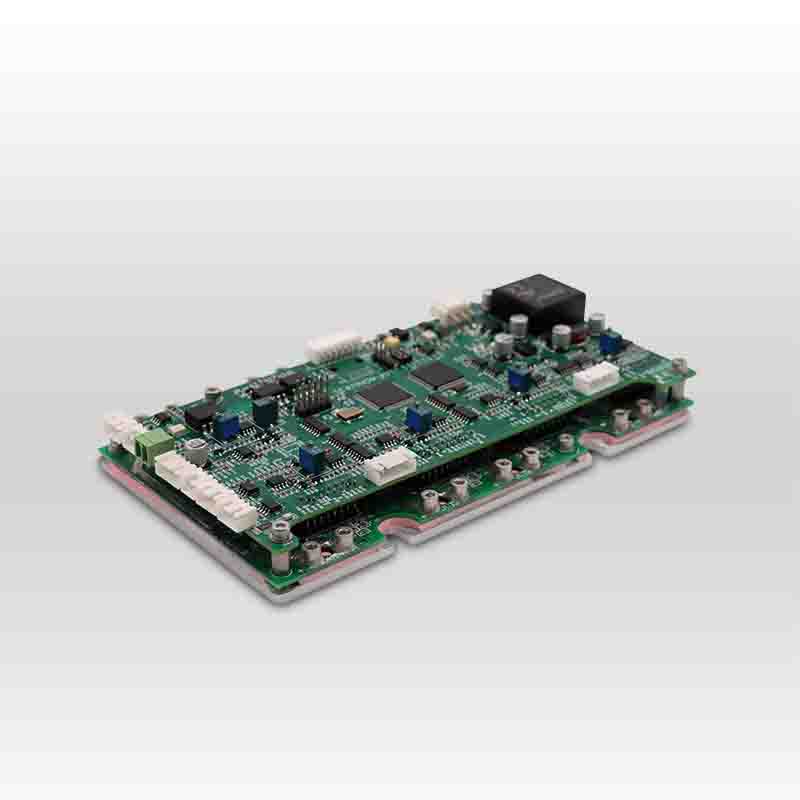

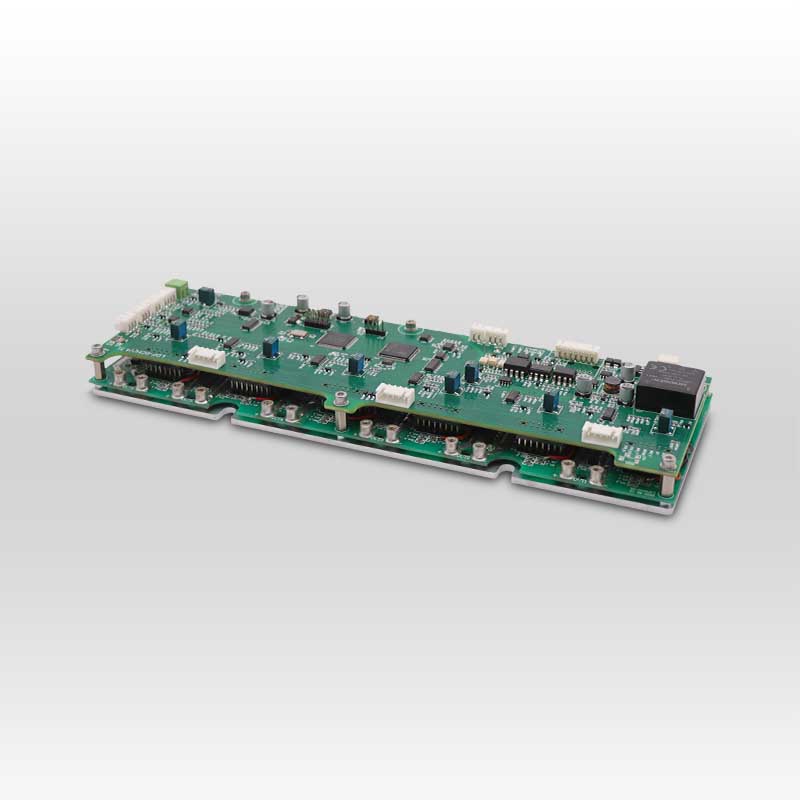

Product features of the driver module:

4-6 channels *20a independent consistent-current force output, every output cutting-edge software may be adjustable and enabled to manipulate respectively.

The output of 30*6=180 constant-current control channels can be extended by a dedicated main control board, and the synchronization error of each channel does not exceed 1uS when switching.

Output voltage 20-180V adaptive (maximum constant-current current decreases with increasing output voltage).

Module power up to 9KW.

The rising and falling edge of the constant-current output current is less than 10US; No overshoot, no recoil.

The output current ripple of constant current is less than ±0.2%; The comprehensive adjustment rate of constant current is less than ±0.5%.

Operating parameters, linkage protection value, alarm value, calibration PD, etc. It can record the running time, store 24 groups of running parameters for direct invocation, store fault records for analysis and upload.

Several control methods: local control, remote RS485 communication control, remote simulation control.

Overtemperature, overcurrent hardware, software interlocking protection, PD hardware interlocking protection to ensure the safety of the laser.

Input voltage detection, undervoltage and overvoltage alarm, to achieve optimal efficiency and facilitate debugging at the same time.

The thermal management function of high-speed accurate power adjustment tube ensures the safety of power tube.

Independent hardware overcurrent protection absolutely avoids overcurrent damage of the rear-band laser.

Real-time detection and control of multi-channel laser power PD, temperature, humidity, flow switch, etc.

Bring the indicator CD drive and control.

A feedforward dedicated constant-voltage source can be developed to reduce power consumption, increase reliability and reduce the difficulty of adjusting the input voltage

Application field

Pump source drive and control of continuous high power fiber laser

Product parameters of the driver module:

Input voltage range | LD terminal voltage + (2.5 to 3.5) V |

The number of LD routes that can be loaded | Ldc4000-4:4 channel; LDC6000 - "way |

The output voltage | 20-180V |

The output current | (4-6)* 0-20A constant current adjustable |

The current quality | Current ripple: ±0.2%; The comprehensive adjustment rate of current is less than ±0.5%. |

Current rise and fall edge | <10US, no overshoot, no recoil |

Maximum output power of the system | Ldc4000-4: not less than 6KW; Ldc6000-6: not less than 9KW |

control | Local control, remote communication control, remote simulation control |

scalability | It can be extended to 30*6=180 constant-current outputs, and the synchronization error of each switch is no more than 1uS |

protect | Over temperature, over current hardware, software interlocking protection, PD hardware interlocking protection |

Chain safeguard | Current, PD interlock protection, start sequence hardware interlock protection |

Temperature and humidity | Working: -25-60℃, 20-90%RH, no condensation; Storage: -40-85℃, 10-95%RH, no condensation |

insulation | pressure:AC500V10mA 60S,Insulation resistance≥10MΩ |

Safety and electromagnetic compatibility | Comply with relevant industry standards |

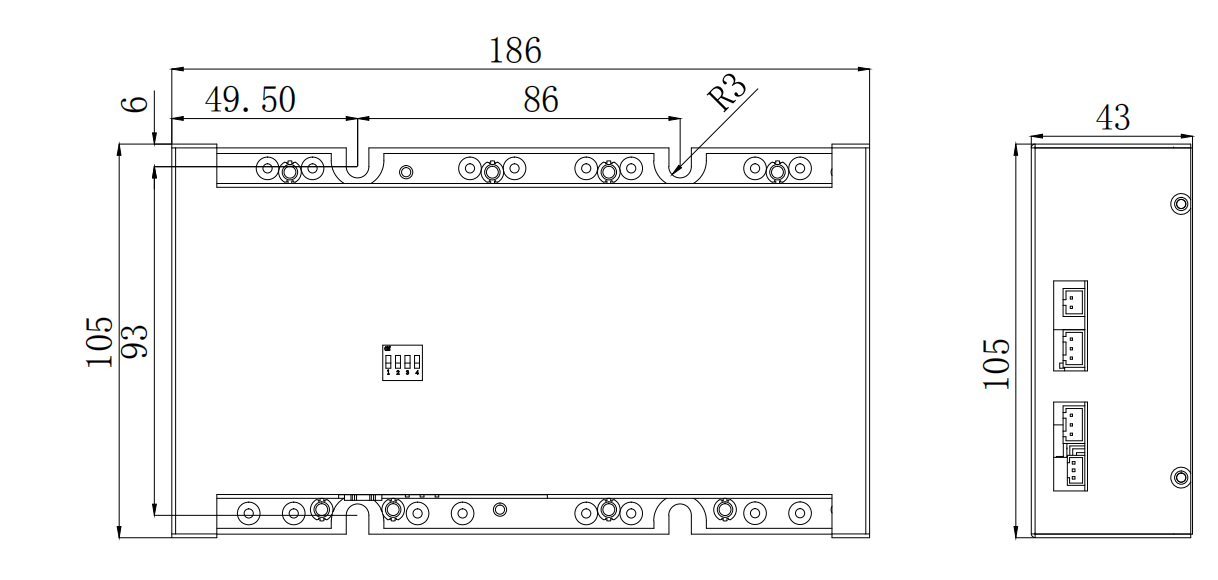

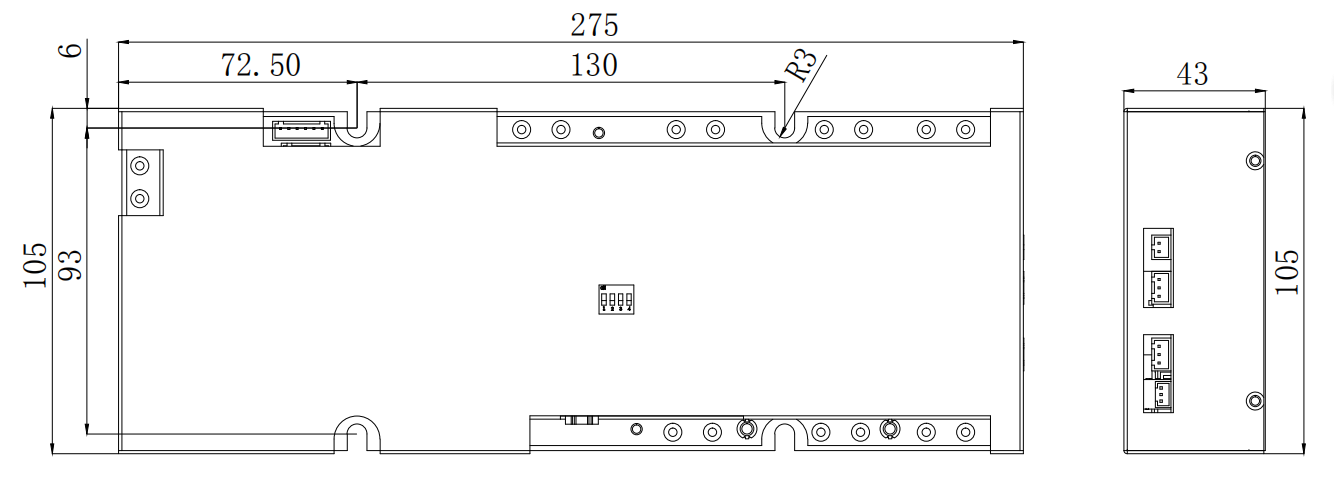

volumeL×W×H (mm) | LDC4000-4:186×105×43 ; LDC6000-6:275×105×43 |

weight | LDC4000-4:0.9KG ; LDC6000-6: 1KG |

冷却方式 | Lining water-cooled |

Overall dimensions of the drive module:

LDC4000-4

LDC6000-6

Related Products

Submitted successfully

We will contact you as soon as possible