How to repair the failure of CO2 laser power supply?

How to repair the failure of CO2 laser power supply?

CO2 laser is widely used in laser engraving, laser cutting and other fields, mainly composed of luminescence system, motion system, control system. Next, our company will briefly introduce how to judge and troubleshoot the failure of CO2 laser power supply from the following two aspects.

Laser has no laser output

1. Check whether the laser tube itself is illuminated (test whether it is illuminated at the optical outlet of the laser tube). If it is illuminated normally, check whether the lens is damaged and the optical path is offset.

2. If the optical outlet of the laser tube is dark, check whether the water circulation is normal (to see whether the water flow is smooth). If the water circulation is normal, check whether the laser power indicator is bright and whether the fan is rotating; If the indicator is off and the fan does not rotate, check whether the input 220V/110V AC power is normal.

3. If the 220V or 110V AC input voltage of the laser power supply is normal, remove the 6-wire green control terminal on the laser power supply and press TEST to manually emit light.

The laser has laser output

1. If the laser has laser output, it indicates that the laser tube and power supply operate normally, and the fault cause is likely to start from the control line. To better solve the fault problem, it is necessary to verify it in the following two ways:

(1) Insert 6 green terminal control wires and short wire WP and G. If the laser emits light, it indicates that the water protection switch is damaged;

② Insert six green terminal control wires. If the laser does not emit light, connect TL and G to short-circuit and check whether the laser emits light.

If the laser fails to emit light or is weak, it indicates that the fault of the laser is likely caused by the fault of the laser power supply or laser tube. If there is a standby laser power supply, a dual-head machine or more than two laser machines, you can replace the existing laser power supply with a normal laser power supply to troubleshoot whether the fault is caused by the laser power supply. Therefore, it is particularly important to have a laser power supply. If the laser fails, it can be troubleshooting in a relatively quick time to facilitate production.

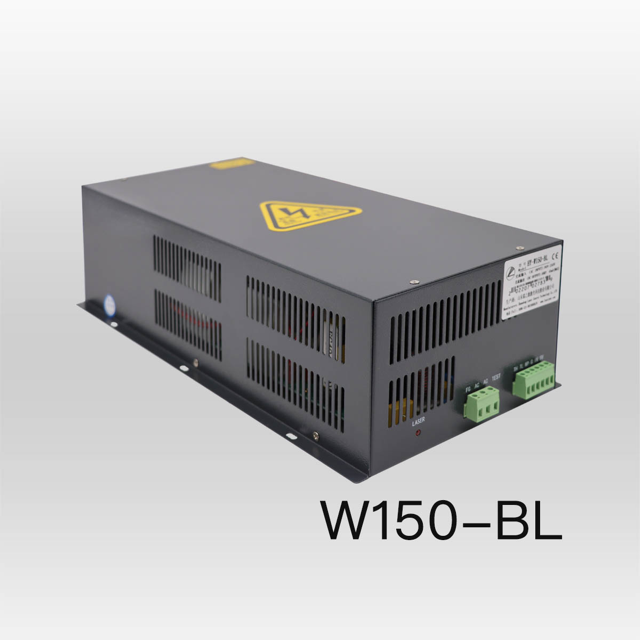

Recommended Products

High power CO2 laser power supply

Targeted design: Special power supply for 200W-1000W high power CO2 laser tube.

With voltage regulator function: With active PFC function, meet the universal input voltage range (AC90-250V,50/60Hz).

More powerful power: in the whole input voltage range, ensure the current 45mA constant.

Output positive and negative ground high pressure suspension: can be used for positive or negative high pressure output, easy to adapt to multi-tube folding applications

High safety of laser equipment: with open circuit protection function, the use of more safe, significantly extend the life of the power supply.

Laser power control is simple: 0~5V analog signal control, also available 5V PWM signal control.

Compact volume, easy installation: for two groups of high voltage output power supply, one group of signals can simultaneously control the output and current of two groups of power supply.

The power supply itself with manual light test function: can quickly judge the power supply and laser fault.

With status indicator light, fault diagnosis is easy.